Greenhouse Gas Emissions of Cars with Various Drive Systems

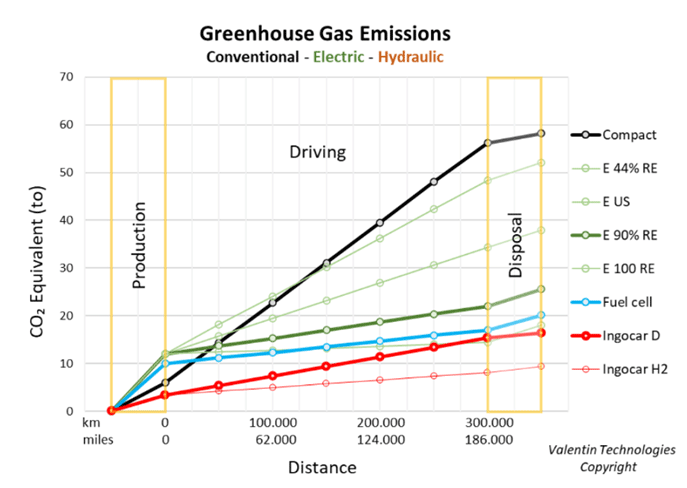

All Green House Gas (GHG) emissions influence the climate, independent of who causes them. The comparison of only “Tank-to-Wheel” (TTW) emissions is flawed since the additional emissions from "Production" (“Well-to-Tank”- WTT) and “Disposal” of BEV's are three times higher than for the Hydraulic Hybrid - or as high as the Hydraulic Hybrids total GHG emissions after 300.000 km (186.000 miles). Therefore, the “Cradle-to-Grave” (CTG) evaluation must be applied to identify the actual influence of traffic on the climate.

The graph "Greenhouse Gas Emissions" (GHG) shows the CO₂ (CtG) emissions of comparable cars with various types of drive-trains: Conventional combustion - Electric (BEV, FCEV) - Hydraulic Hybrid. The data are from the publications [1][2][3] and VTI simulations.

The graph "Greenhouse Gas Emissions" (GHG) shows the CO₂ (CtG) emissions of comparable cars with various types of drive-trains: Conventional combustion - Electric (BEV, FCEV) - Hydraulic Hybrid. The data are from the publications [1][2][3] and VTI simulations.

The emissions from “Disposal” are assumed to be 30% of that for “Production” since more sufficient data are currently not available. Eventually, all parts of a car must be recycled, even batteries after a second use in a non-automotive application. The carbon fiber CFRP accumulator has an infinitive life, but it should be sufficient for at least a second life-cycle or double the life of a battery or a fuel cell, as assumed here. The material for the accumulator is recyclable. The TTW data of the Ingocar take the high use of energy for fabricating the CFRP material (14x as steel, but 1/4 in weight) into account.

BEV´s operate, compared with Hydraulic Hybrids, with a higher drivetrain efficiency, but must move 3 x the weight, and recuperate less than one third of the energy from braking. The graph shows BEV's provided with electricity from sources with various % of renewable energy (RE). The 90% RE, as used in this comparison, are higher than the in long terms expected 85% of a power mix. Conventional power plants are always needed to provide the remaining 15% of energy when sufficient RE is not available. An electric battery for the remaining 15% will not lower the overall GHG emissions.

Imported “Green” hydrogen for Fuel Cell Vehicles (FCEV) is expected to be an economical alternative by 2025. [4] The less pressure and tempe-rature sensitive HFPE with Pressure Impulse Charger & Compounder (PICC), insulated combustion chamber, and exhaust energy recuperation is expected to reach a comparable maximal efficiency of 63%, while being significantly more robust (life expectancy), smaller, and less expensive than a fuel cell. (7) In addition, the HFPE operates with Hydrogen of lower purity and costs.

The "Compact" car (CC) weighs about 1.360 kg (3,000 lbs.) and reaches 5,5 L/100km (43 MPG) (Average VW Golf 1.450 kg (3.190 lbs.). When comparing the BEV with 90% RE, the Hydrogen driven Ingocar H reduces the CO₂ by 60% and emits during its whole lifecycle of 300.000km (186,000 miles) less CTG Emissions than either the BEV or FCEV during Production (WTT) only.

The platform of the Ingocar and Ingocar H (Hydrogen) essentially differ in the type of the fuel injection system (Diesel or H₂ injector) for the HFPE and possibly the size of one pressurized H₂-CFRP accumulator section of the platform. Otherwise, they are indentical.

The hydrostatic drive system is applicable to heavy trucks and provides nearly the same benefits as for the car. In comparison with heavy duty BEV-Trucks, a payload increase of 6 to 8 to, and noticeably more floor space can be achieved. Travel distance and performance are more than doubled, and a 35% reduction in fuel consumption (efficient engine, braking energy recovery) reduce the Total Cost-of-Ownership (TCO) by 12% to 15%.

A new study [5] compares cars and light and heavy trucks, equipped with a battery electric powertrain (BEV), a hydrogen powertrain (fuel cell or ICE) and a conventional, gasoline driven ICE. Based on the availability of the powertrain technology and type of energy (electricity, hydrogen, fuel), the hydrogen powertrains provide to most benefits for all three types of vehicles under WTW considerations.

The study considers a hydrogen driven ICE with 42.2% efficiency. The FPE of the Hydraulic Hybrid has an expected efficiency of 63% due to a very high mean effective pressure (35 bar bmep), low mechanical friction, low heat radiation (LHR) of the ceramically coated combustion chamber, Rankine Cycle to reduce the exhaust heat losses, and pressure impulse charger. Considering the full recuperation of braking energy [6], it is expected that the Hydraulic Hybrid provides a noticeable reduction of CO₂ equivalents in a CTG comparison. The higher costs for Hydrogen are expected to be more than compensated through the reduced consumption of 65%.

In this study, if hydrogen and electricity are fully produced by RE, both hydrogen drive systems are largely equal regarding CO₂ equivalents in a WTW comparison. In a pure TTW comparison, the BEV (cars, trucks) have the lowest CO₂ emissions, but the highest during Production (WTT) and 'Disposal'. Independent from the type of energy supply, the Ingocar would produce the lowest emissions in all sections (CTG).

To the benefits: The infrastructure for vehicles with the Advanced Hydrostatic Drivetrain (Diesel) is established. The large amount of additional emissions from producing electric drive systems can be avoided, and the required CO₂ goal (33 g/km) for 2050 can be reached 20 years earlier. A further reduction of emissions (-40%) through the Ingocar H requires production facilities and supply chains which are then timely less critical and significantly less costly to build.

-

ADAC/Joanneum Research. "Der Treibhausgas-Ausstoß eines Autolebens" 08, 2019

-

The Wall Street Journal/University of Toronto. “Are Electric Cars Better for the Environment?", March 23, 2021

-

MTZ - Motor Technische Zeitschrift. "Ökobilanzen – Strittig, aber alternativlos", Thomas Siebel, April 2021.

-

MTZ - "Wasserstoff - Importoption sticht Vorbehalte aus", Dr. Klaus Schmitz, Arthur D. Little, Juli-August, 2021

-

42nd International Vienna Motor Symposium 2021, Hydrogen Powertrains in Competition to Fossil Fuel based Internal Combustion Engines and Battery Electric Powertrains. Sens, Danzer, von Essen, Bauer, Wascheck, Seebode, Kratsch.

-

Exploring the Pathway to High Efficiency IC Engine through Exergy Analysis of Heat Transfer Reduction. SAE Report 2013-01-0278. Bernard Johnson and Chris Edwards, Stanford University, April 2013

-

Powering Sustainable Futures, Diesel Fights Back: Innovations in Traditional Engines. Diesel Progress Summit, October 2020, Dr. Andy Nobel, Ricardo.